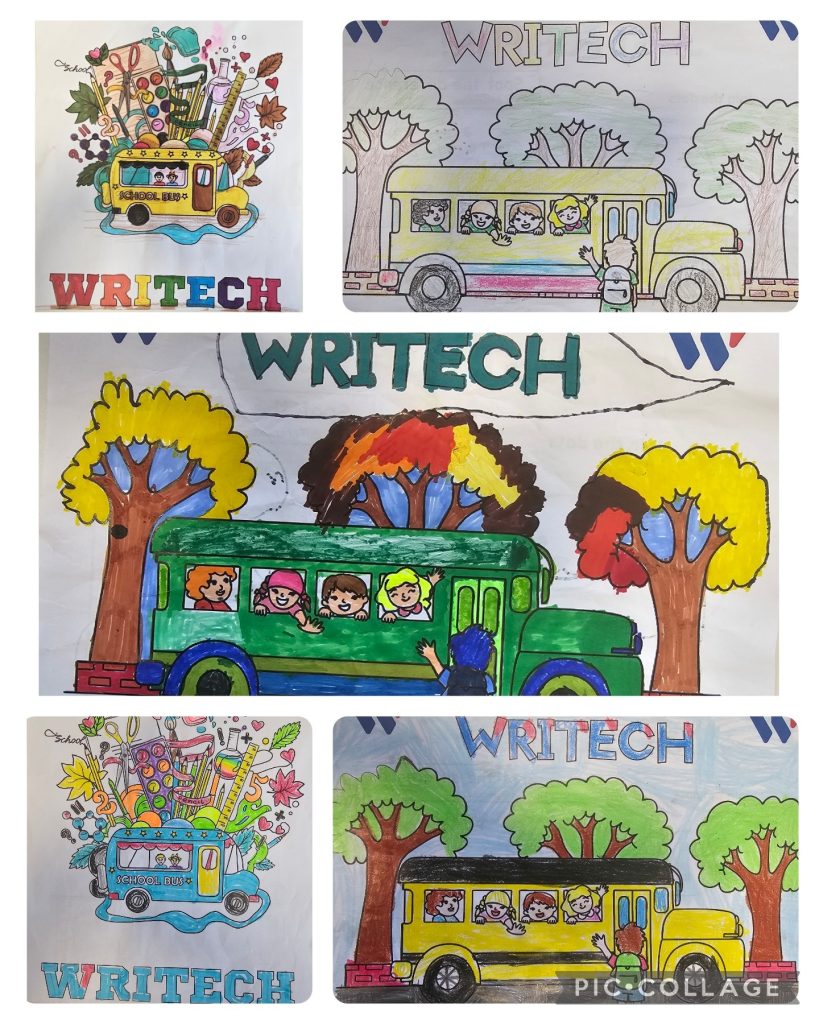

Writech named one of Ireland’s Best Managed Companies 2025 for the second year running

Writech is delighted to announce that it has been recognised as one of Ireland’s Best Managed Companies for the second year in a row. The award, presented at a ceremony…